For order or price inquiry of 23KM-K240-11V MinebeaMitsumi ( NMB ) Please click on Buy Order button and fill the RFQ form we will check out inventory and offer you our best price.

Quick Access

About

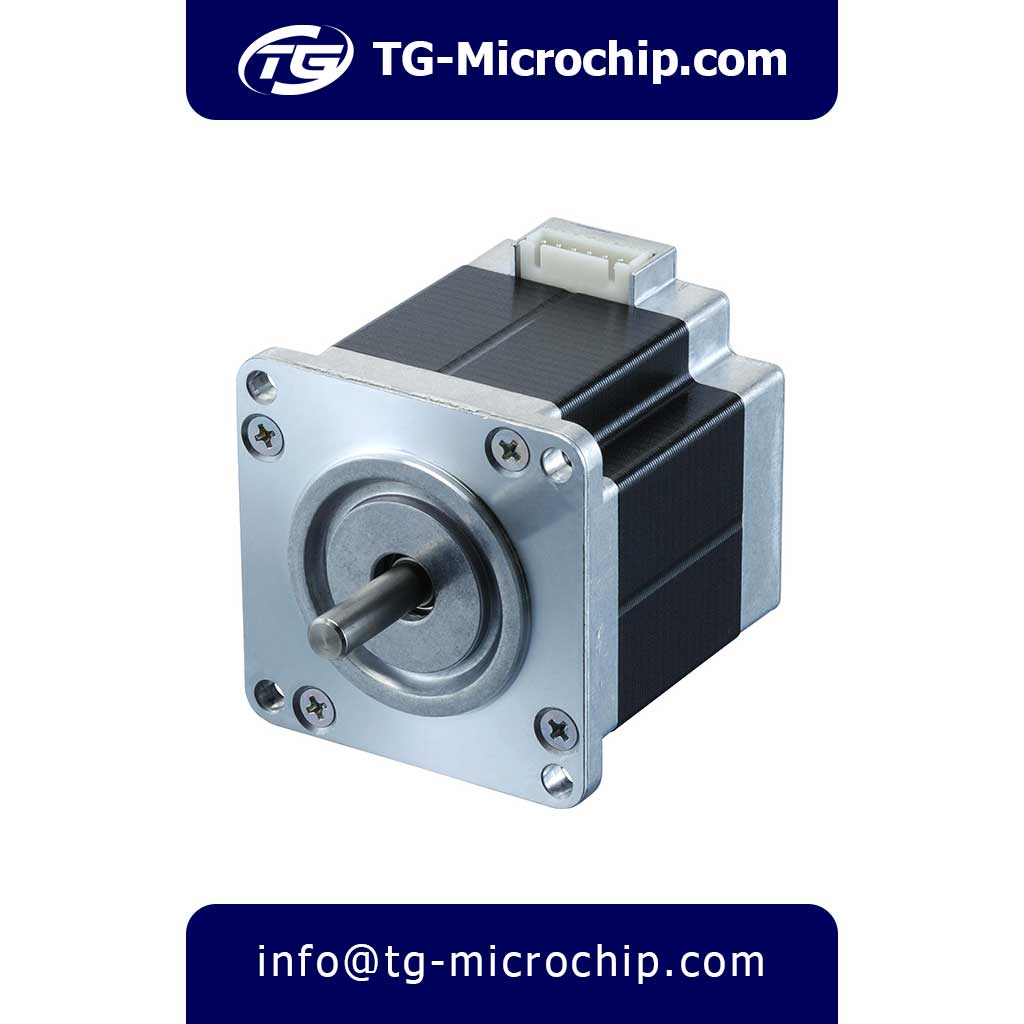

The Minebea 23KM-K240-11V is a hybrid stepping motor from MinebeaMitsumi’s 23KM-K series, designed for precision motion control in industrial and automation applications. As part of the standard hybrid stepper motor lineup, it features a 1.8° step angle (200 steps/revolution) and operates with a 6-wire configuration, supporting both unipolar and bipolar drive modes for flexibility in system integration. The motor is built with a NEMA 23 frame (56.4 × 56.4 mm) and incorporates ball bearings for smooth, reliable operation in demanding environments.

Key electrical specifications include a rated current of 2.0 A per phase (bipolar mode) and a holding torque of 7 kg·cm (~686 mN·m), making it suitable for applications requiring precise positioning and moderate torque. The motor’s 4.5 Ω phase resistance (bipolar) and ~3.5 mH inductance ensure compatibility with common stepper drivers like the DM542 or TB6600. Its 6-wire design allows for multiple wiring options, including full-coil or half-coil excitation, depending on the driver’s requirements.

Mechanically, the 23KM-K240-11V features a 6 mm diameter shaft with a standard 20 mm length, enabling direct coupling with pulleys, gears, or lead screws 5. The motor’s IP40-rated enclosure provides basic dust protection, while its Class B insulation (130°C) ensures durability in industrial settings. With a weight of 466 g, it balances compactness and performance, fitting seamlessly into CNC machines, 3D printers, and medical equipment.

While the exact datasheet for this model isn’t directly available in the search results, the 23KM-K series is well-documented, with variants like the 23KM-K249U and 23KM-K040-02V sharing similar specs. For detailed torque-speed curves or custom configurations, MinebeaMitsumi offers technical consultations and customization services. The motor’s broad compatibility and robust design make it a reliable choice for automation, robotics, and precision manufacturing applications.

Key Features

- Motor Type

- Hybrid (PM + VR) 2-phase stepper motor

- Step Resolution

- 1.8° step angle (200 steps/revolution)

- Electrical Specifications

- 6-wire configuration (supports unipolar/bipolar drive)

- Rated current: 2.0 A/phase (bipolar)

- Phase resistance: 4.5 Ω (bipolar) / 2.3 Ω (unipolar middle tap)

- Inductance: ~3.5 mH/phase

- Mechanical Specifications

- NEMA 23 frame size (56.4 × 56.4 mm)

- Single-ended shaft: 6 mm diameter × 20 mm length

- Ball bearing construction

- Torque Characteristics

- Holding torque: 7 kg·cm (686 mN·m)

- Detent torque: ~20 mN·m

- Wiring & Connectors

- Standard 6-wire termination (flying leads)

- Compatible with JST XHP-6 connectors

- Environmental Ratings

- Operating temperature: -20°C to +50°C

- Insulation class: B (130°C)

- Protection: IP40 (dust protected)

- Physical Properties

- Weight: 466 g

- Mounting: 4× M3 threaded holes (NEMA 23 pattern)

- Compatibility

- Works with common stepper drivers (L298N, TB6600, DM542, etc.)

Applications

Applications of Minebea 23KM-K Series Stepper Motors:

1. Office Automation Equipment

- Printers & Copiers: Paper feed mechanisms, scanner positioning, and toner cartridge alignment.

- Multifunction Devices: Automated document feeders (ADFs) and precision paper handling.

- Facsimile Machines: Drum rotation and paper transport systems.

2. Industrial Automation & Machinery

- CNC Machines: Axis control for milling, drilling, and engraving.

- Robotic Arms: Joint actuation and gripper positioning.

- Packaging Systems: Conveyor belt synchronization and product sorting.

- Assembly Lines: Pick-and-place robots and precision part alignment.

3. Medical & Laboratory Devices

- Syringe Pumps: Precise fluid dispensing in infusion systems.

- Diagnostic Equipment: Sample tray movement in analyzers and imaging devices.

- Dental Tools: Adjustments in chairside CAD/CAM systems.

4. Semiconductor & Electronics Manufacturing

- Wafer Handling Robots: Precision movement in cleanrooms.

- PCB Assembly: Component placement and laser drilling.

- 3D Printers: Extruder and bed positioning.

5. Consumer & Commercial Electronics

- Security Cameras: Pan-tilt-zoom (PTZ) mechanisms.

- Vending Machines: Product dispensing and door actuation.

- Slot Machines: Reel spinning mechanisms.

6. Aerospace & Defense

- Drone Gimbal Controls: Stabilization for cameras and sensors.

- Satellite Antennas: Precision pointing and tracking.

7. Automotive & Transportation

- Dashboard Instruments: Needle actuation in analog gauges.

- EV Battery Systems: Cooling fan control.

8. Specialized Industrial Uses

- Textile Machinery: Thread tensioning and loom control.

- Amusement Rides: Motion control for interactive attractions.

Advantages

Comprehensive Applications of Minebea 23KM-K Series Stepper Motors:

- High Positioning Accuracy

- The hybrid design with permanent magnets ensures precise step-by-step movement, ideal for applications requiring exact positioning.

- Smooth Operation

- Ball bearings reduce friction and vibration, enabling quiet and stable performance even during continuous use.

- Versatile Drive Compatibility

- The 6-wire configuration allows flexibility in connecting to both unipolar and bipolar drivers, accommodating different control systems.

- Durability in Harsh Environments

- Robust construction with IP40-rated housing protects against dust and minor debris, extending motor lifespan in industrial settings.

- Easy Integration

- Standard NEMA 23 frame size and mounting pattern simplify mechanical installation in existing machinery and automation systems.

- Reliable Performance

- Stable torque output across a range of speeds ensures consistent operation in demanding applications like CNC and robotics.

Specifications

| Category | Specification |

|---|---|

| Manufacturer | MinebeaMitsumi (formerly Minebea) ( NMB ) |

| Product Category | Hybrid Stepper Motors |

| Product Type | 2-Phase Bipolar/Unipolar Stepper Motor |

| Series | 23KM-K Series (Standard Industrial Grade) |

| Model Number | 23KM-K240-11V |

| Motor Type | Permanent Magnet Hybrid Stepper |

| Step Angle | 1.8° (200 steps/revolution) |

| Holding Torque | 7 kg·cm (≈686 mN·m) |

| Rated Current/Phase | 2.0 A (Bipolar) / 1.4 A (Unipolar) |

| Voltage Rating | 12–24 V DC (typical) |

| Phase Resistance | 4.5 Ω (bipolar) / 2.3 Ω (unipolar middle tap) |

| Inductance/Phase | ~3.5 mH (typical for 23KM-K series) |

| Rotor Inertia | ~85 g·cm² (estimated) |

| Wiring Configuration | 6-wire (A, A̅, Common / B, B̅, Common) – Supports both unipolar & bipolar modes |

| Shaft Type | Single-ended, round (D-cut optional in some variants) |

| Shaft Diameter | 6 mm (±0.01 mm) |

| Shaft Length | 20 mm (standard) / Custom lengths available |

| Body Dimensions | 56.4 × 56.4 × 41 mm (NEMA 23 frame) |

| Weight | 466 g (±10 g) |

| Bearing Type | Shielded ball bearings (pre-lubricated) |

| Insulation Class | Class B (130°C) |

| Ambient Temperature | -20°C to +50°C (operational) |

| Protection Rating | IP40 (standard dust protection) |

| Mounting | Face-mounting (NEMA 23 flange) with 4x M3 threaded holes |

| Connector Type | Flying leads (bare wires) / Optional JST connectors |

| Compliance | RoHS compliant, CE marked (varies by region) |

| Applications | CNC routers, 3D printers, medical devices, packaging machines, robotics |

Comparison with Similar Components

| Feature | Minebea 23KM-K240-11V | Minebea 23KM-K249U 14 | Minebea 23KM-K723-11V 8 | Standard NEMA 23 Hybrid Motor (Generic) |

|---|---|---|---|---|

| Motor Type | Hybrid (PM + VR), 2-phase | Hybrid, 2-phase (Unipolar) | Hybrid, 2-phase (Custom) | Hybrid, 2-phase |

| Step Angle | 1.8° | 1.8° | 1.8° | 1.8° |

| Holding Torque | 686 mN·m (7 kg·cm) | 420 mN·m | ~540 mN·m (estimated) | 300–800 mN·m (varies) |

| Rated Current/Phase | 2.0 A (Bipolar) | 1.4 A (Unipolar) | 3.0 A (estimated) | 1.5–3.0 A |

| Phase Resistance | 4.5 Ω (bipolar) / 2.3 Ω (unipolar) | 1.3 Ω (unipolar) | 0.8 Ω (custom) | 1.0–5.0 Ω |

| Inductance/Phase | ~3.5 mH | 1.9 mH | Not specified | 2.0–6.0 mH |

| Wiring Configuration | 6-wire (A, A̅, COM / B, B̅, COM) | 6-wire (Unipolar) | 8-pole (custom) | 4/6/8-wire |

| Shaft Diameter | 6 mm | 6 mm | 6 mm | 6 mm |

| Frame Size | NEMA 23 (56.4 × 56.4 mm) | NEMA 23 | NEMA 23 | NEMA 23 |

| Weight | 466 g | 470 g | Heavier (length: 76 mm) | 400–600 g |

| Applications | CNC, 3D printers, medical devices | Printers, office automation | Industrial automation | General automation |

| Customization | Optional (via MinebeaMitsumi) 115 | Limited | Rare (discontinued) | Limited |

Key Differentiators

- Torque & Current

- The 23KM-K240-11V offers higher torque (686 mN·m) than the 23KM-K249U (420 mN·m) but lower than the custom 23KM-K723-11V (~540 mN·m) 48.

- Higher current (2.0 A) makes the 23KM-K240-11V suitable for high-power applications compared to unipolar variants.

- Wiring & Flexibility

- The 6-wire design of the 23KM-K240-11V supports both unipolar and bipolar drives, unlike the 8-pole custom 23KM-K723-11V 8.

- Generic NEMA 23 motors may lack standardized wiring (e.g., 4-wire only).

- Customization

- Minebea’s 23KM-K240-11V can be tailored for niche applications (e.g., medical, aerospace) 15, while the 23KM-K723-11V is a discontinued custom model.

- Physical Dimensions

- The 23KM-K723-11V is longer (76 mm) and heavier, suited for high-torque industrial uses, whereas the 23KM-K240-11V balances size and performance 8.

Recommendation

- For precision tasks (CNC, robotics): 23KM-K240-11V (optimal torque/wiring).

- For legacy systems: 23KM-K723-11V (if available).

- For low-power devices: 23KM-K249U (unipolar).

Frequently Asked Questions (FAQs)

General Specifications

1. What is the step angle of the 23KM-K240-11V?

It has a 1.8° step angle (200 steps/revolution), standard for hybrid stepper motors.

2. What is the holding torque?

686 mN·m (7 kg·cm) under bipolar drive conditions.

3. Is this motor unipolar or bipolar?

It supports both modes via its 6-wire configuration (A, A̅, COM / B, B̅, COM).

Electrical & Wiring

4. What is the rated current per phase?

2.0 A in bipolar mode; lower in unipolar (e.g., ~1.4 A for similar models).

5. How do I wire the motor?

Follow the standard 6-wire pinout:

- Pin 1: A+

- Pin 2: A COM

- Pin 3: A-

- Pin 4: B+

- Pin 5: B COM

- Pin 6: B-

6. Can I use a 4-wire driver with this motor?

Yes, but only in bipolar series or parallel mode by omitting the COM wires.

Mechanical & Installation

7. What is the shaft diameter and length?

6 mm diameter × 20 mm length (standard).

8. Is the motor compatible with NEMA 23 mounts?

Yes, it uses a NEMA 23 frame (56.4 × 56.4 mm) with 4x M3 mounting holes.

9. Does it include bearings?

Yes, it uses high-precision ball bearings manufactured in-house for smooth operation.

Applications & Compatibility

10. What are typical applications?

CNC machines, 3D printers, medical devices, robotics, and factory automation equipment.

11. Which drivers are compatible?

Works with common drivers like DM542, TB6600, or L298N (bipolar recommended for full torque).

Customization & Support

12. Can MinebeaMitsumi customize this motor?

Yes, they offer technical consultations, sample productions, and optional functionalities (e.g., custom shaft lengths).

13. Where is the motor manufactured?

Produced in Japan, Thailand, and the U.S. under vertically integrated processes.

Troubleshooting

14. The motor vibrates excessively. What could be wrong?

Check for:

- Incorrect current settings on the driver.

- Mechanical misalignment or loose couplings.

- Resonance issues (use microstepping or dampers).

15. How do I resolve overheating?

Ensure the driver’s current matches the motor’s rated 2.0 A/phase and provide adequate cooling.

Datasheet

23KM-K240-11V MinebeaMitsumi ( NMB ) datasheet

Contact us for More Information

Contact us for more information and stock inventory inquiry of 23KM-K240-11V MinebeaMitsumi ( NMB ).

China Email : info@tg-microchip.com

Hong Kong Email : hk@tg-microchip.com

Russia Email : russia@tg-microchip.com